MP

PLANETARY MIXER

OPTIONS AVAILABLE

SKIP FOR AGGREGATE LOADING

Skip hoist is available for all sizes of MP mixers. The Twin Drum hoist equalizes the load and prevents the skip bucket from falling in case of cable failure. Slack cable detectors also give the most reliable and safe operation.

CEMENT AND WATER SCALES

All MP mixers can be equipped with the weighing hoppers for Cement and Water. They are fixed to the mixer tank and preassembled in the factory to minimize the erection time of the plant at the jobsite.

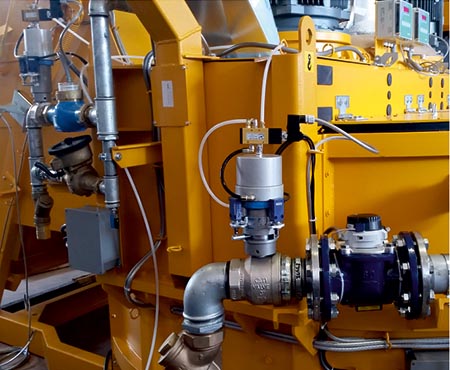

WATER FLOWMETER

As an alternative to the water scale, water can be measured by a flowmeter.

In some applications it is basically used for the moisture correction of the batch in conjunction with a moisture probe.

AGGREGATE HOLDING HOPPER

This accessory is strongly recommended to allow the mixer to reach its nominal productivity.

Preassembled in the factory, it is equipped with an OMG Sicoma butterfly valve driven by the hydraulic power pack of the mixer.

BOTOMATIC DISCHARGE DOOR

For slurry / bitumen mixtures and for powder blending, the use of the special “botomatic” door makes the tank perfectly leakage proof. This is particularly critical when the tank is pressurized (due to gas injection) or de-pressurized.

SIDE ACCESS DOOR

Whenever the access from the top cover to the tank is impossible or too difficult, the side access door is the right solution. This option is also recommended for special mixtures in order to improve the cleaning of the tank.

HIGH SPEED AGITATOR

The function of this additional device depends on the type of mixture, speed and blade configuration. For dry mix, it increases the dispersion of the materials whereas for low water mixtures it crushes the possible lumps generated by the mixing.

HIGH PRESSURE WASHING SYSTEM

Using the unique feature of the hollow shaft of the OMG Gearbox, the high pressure pipe reaches the center of the machine allowing the washout jets to be mounted under the scraping arms. All nozzles are adjustable to cover all spots for a high efficiency cleaning.

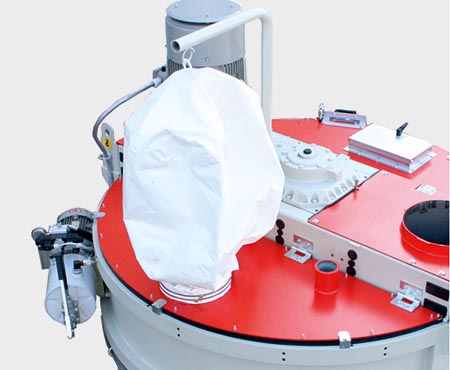

DUST COLLECTOR AIRBAG

During the aggregate loading into the mixer from a holding hopper, the Dust Collector Bag absorbs the air shock generated by the fast inrush of the material. The function of the airbag is very important for dust containment, in conjunction with an active filter.

FLOOR MOUNTED MOISTURE PROBE

The production of high quality concrete usually requires a moisture measurement in the mixer, in order to control the water content in the mix. Upon request, all Planetary Mixers can be equipped with moisture probes installed at the floor level.

PROBE CLEANING BLADE

In case a floor mounted probe is installed, we recommend using a rubber cleaning blade which cleans the surface of the sensor at every rotation of the planetary gearbox, improving the quality of the measurement.

ROTATING MOISTURE PROBE

Due to the hollow main shaft (unique feature of OMG Gearbox), MP Mixers can be equipped with a moisture probe which is fixed to the scraping arm and rotating into the mixture. The probe cables are connected to the control system through a rotating collector.

HYDRAULIC SAMPLING BOX

All Planetary mixers can be equipped with a sampling box to take samples of material before the discharge, typically used to prepare test cubes. The operator can collect the sample easily and safely without stopping the mixer and opening the top cover.

BELT TRANSMISSION

In case the mixer must be installed in a plant with a reduced height dimension, it is possible to install the mixer motor at the side of the tank and to use a belt transmission between the motor and the gearbox. This solution is typically used for retrofits or mobile plants.

MANUAL CONTROL PANEL

Mounts on the mixer, allowing major mixer functions to be controlled locally to make cleanout, testing and maintenance easier.

DISCHARGE DOOR SAFETY GUARD

When the service platform of the mixer is installed under the discharge door, it is necessary to use a protection guard to keep the operators safe during the rotation of the door sector. This safety guard can also be dust proof when the mixer works with dry mixes.

HYDRAULIC COUPLING

Gives long service life by reducing the high mechanical stress in conditions such as repeated startup with a full load.

STAINLESS STEEL TANK AND MIXING TOOLS

Whenever the material to be mixed must be contamination free or when the ingredients are chemically aggressive, it is recommended to use special materials (such as Stainless Steel) for the lining of the pan and for the mixing tools.