MAO

TWIN SHAFT MIXER

OPTIONS AVAILABLE

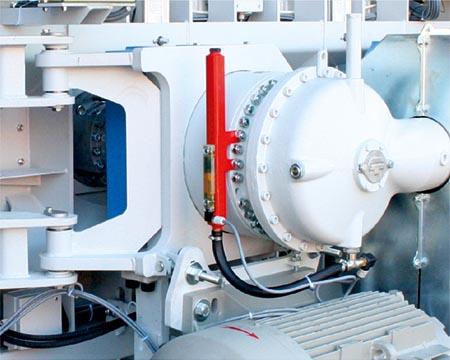

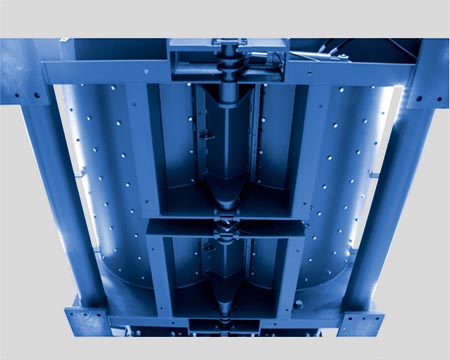

SWING OUT DRIVES (SWOD Option)

This unique option for SICOMA Twin Shaft Mixers was developed over the last years to make any maintenance to the shaft supports easier and faster . The full drive assembly (Motor, Pulleys and Gearbox) is hinged to the side of the mixer tank and it can be swung out easily without the need of cranes or any lifting device.

In case of unplanned maintenance, the downtime for the plant is minimized, resulting in a extremely low maintenance cost.

SKIP HOIST

The loading skip for the aggregates is available for the MAO mixers up to the size 6000/4000. The hoist has two grooved drums on the same shaft.

The skip cable has an anti free-fall block in case of cable failure while two limit switches constantly check its tension.

Upon request, the double speed for ascent and descent is available, as well as an inverter based controller to customize speed at its best.

BATCH FEEDING SYSTEM

Due to the particular reinforced structure, SICOMA Twin Shaft Mixers can be equipped with a Batch Feeding System stacked on the tank using the top fixing plates on the tank frame. This system is composed by Aggregates Holding Hopper, Cement Scale, Water Scale and Air Bag. Being everything preassembled at the factory before the shipment, the installation time at the jobsite is extremely short.

HIGH PRESSURE WASHOUT

Two high pressure water pipes are placed above the shafts with as many nozzles as the number of arms. These spray bars are operated by a gearmotor and rotate so that the jets reach every spot for an effective cleaning. The washout has to be carried out at the end of each mixing cycle and the waste water is used for the next mixing.

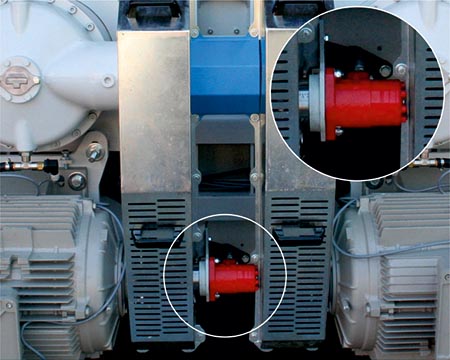

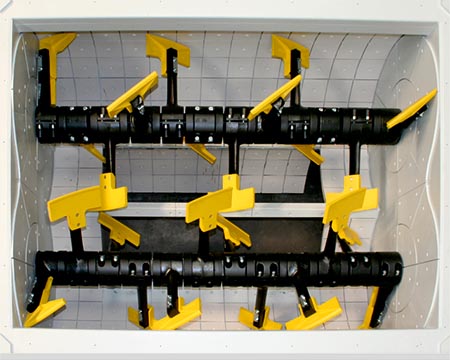

SLOW MOTION DRIVE

This option is based on an auxiliary motor which can rotate the shafts at low speed (1 RPM). By using a button switch, the shafts can run safely also with the inspection doors open. The cleaning as well as the regular maintenance (such as periodic blade adjustment) are simplified and faster. We recommend to choose the Manual Control Panel including all devices to operate the Slow Motion Drive.

HIGH PRESSURE WATER UNIT

With a reservoir of minumim 200 liters, the High Pressure Water Unit supplies the spraybars installed in the mixers using a piston pump driven by a motor with minimum power of 15 kW. The pressure and flowrate are selected depending on the mixer size (min 60 Bar).

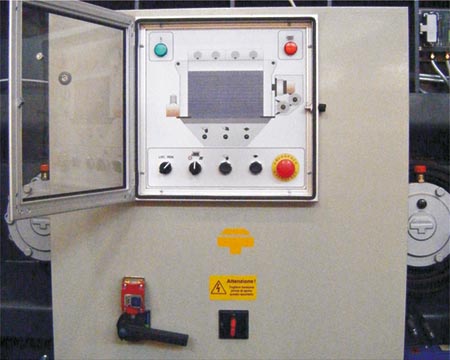

MANUAL CONTROL PANEL

The mixer can be equipped with the Manual Control Panel which can operate the mixer in Manual Mode with the following buttons: Start/Stop of the mixer motors, Open/Close Discharge Door and Emergency Stop. This Panel can also operate the Slow Motion Drive, if present.

REDUCED DISCHARGE DOOR

The reduced size of the discharge door allows the use of a small discharge chute. As a consequence, the supporting structure of the mixer can be shorter compared with the standard twin shaft mixers.

DOUBLE DISCHARGE DOOR

The mixer can be equipped with two independent discharge doors to pour the concrete in two different places. One of the limitations of the twin shaft mixers is then overcome.

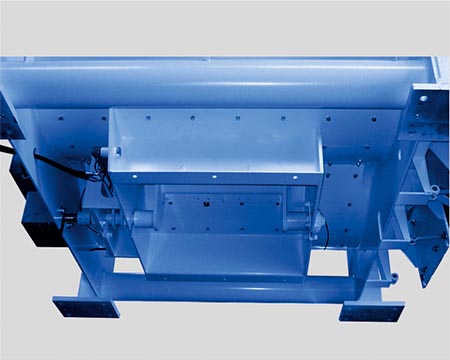

BOMB BAY DOOR

All SICOMA Twin Shaft Mixers can be equipped with the Bomb Bay Door which allows the bottom of the mixer tank to be opened for nearly half of its surface. The discharge is extremely fast also in case of low slump concrete.

This option is particularly important in case of RCC production and loading on dump trucks.